Rammed Earth Construction Part II - Mixing the Mud

February 28, 2009

(For a list of all of the Rammed Earth Construction blog entries, go to the Index Page.)

Selecting the right mud mixture is key to building a successful, durable mud or rammed earth building. Different kinds of earth have different qualities, and mixing them in the right ratio is what provides cohesion. First, here is a brief overview of the different types of mud that we will be using:

AGGREGATE

The aggregates will bear the weight of the walls and strengthen the structure. Any of these aggregates can be used in rammed earth construction. You should chose the one that is most easily available in your area. For our rammed earth project we used both pebbles and brick chips.

1) Pebbles

The pebbles are about 1/2" to 1" in diameter. Pebbles are large (comparatively) and round; like marbles, if we pile them on top of each other, they will just roll apart. Consequently we need other types of earth to adhere the pebbles together.

2) Brick Chips

2) Brick ChipsThis is a readily available form of aggregate in Bangladesh as there are many brick fields. The brick chips are also 1/2" to 1" in diameter. Though they are not as round and smooth as the pebbles, they will also slide if merely piled on top of each other.

3) Crushed Concrete

3) Crushed ConcreteThis is a great way to recycle old buildings. Pieces of old, crushed concrete (or rubble) can be ground into 1/2" to 1" pieces and used as aggregate.

4) Gravel

This is another good form of aggregate that is often also used in concrete. Gravel is not very easy to come by in Bangladesh, however.

EARTH

The earth is what holds the walls together. It is important to get the right mix of earth and aggregate so that you minimize shrinkage (and therefore cracks) and erosion while maximizing strength and durability.

5) Sand

Sand is important for strength, cohesion, and shrinkage. As any child who has ever played on the beach can tell you, wet sand is a great building material. The water molecules act as a glue that holds the sand together. Wet sand can be molded into an infinite variety of shapes. When the water evaporates, however, the bonds are broken and the sand reverts into a shapeless pile. Conseqently, another type of earth is needed to hold the sand particles together...

6) Clay

6) ClayClay is a very plastic material. Because of its oblong shape, clay particles slide easily over each other. Wet clay slides the easiest (picture two pieces of glass with a thin layer of water between them and you will get the idea.) When the water dries, the clay shrinks, bringing the clay particles closer together and making it very hard. Because clay shrinks quite significantly, however, many cracks will form in the wall (picture a dry field of mud) unless aggregate is added. There are different types of clays ranging from sandy to sticky. The stickier the clay, the tighter the bond, but the more cracks you will have. On our project we used two different types of clay: "sticky clay" and clay that we dug up from the project site which was redder and sandier. You can tell how sticky the clay is by squeezing it in your hand. The more it holds its shape, the stickier the clay is.

The trick is to find the right mixture of clay, sand, and aggregate. A good rule of thumb is 40% aggregate, 30% sticky clay, 30% mud from the site. You should do tests, however to determine what the right mud mixture is for you.

On our project, the "sticky clay" was too wet to mix in with the aggregate and site mud. (If it is wet, the mud just clumps together and doesn't blend in with the other components.) We tried to break it into smaller pieces and set it in the sun to dry, but it was too labor intensive to be able to practically implement on a large scale. We did end up using the dried sticky mud to create the clay plastering, however. Our final ratio was 5 parts clay from site, 1 part brick chips, and 1.5 parts pebbles. Because we had to omit the sticky clay, our mixture was not as strong, so we had to insert more erosion breakers. (See Part III - Preventing Erosion for more information.)

TESTING YOUR MUD

There are several tests that you can do to determine what type of mud you have and how well it will work in rammed earth construction.

1. Squeeze Test

This is a simple test to determine the quantity of clay in your mud. You take a handful of moist earth (not wet, not dry) and squeeze it. The degree to which it holds its shape after you open your hand is an indicator of how much clay is in the mix.

This earth was taken from the project site. Unfortunately the photos are a bit out of focus, but I think you can still get the idea...

Sticky Clay Squeeze Test

This clay was brought in from another site. It is true "sticky" clay.

You can see that it keeps its exact form after performing the squeeze test

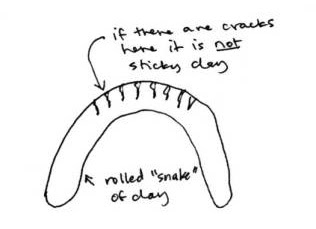

This is a simple test to determine if your clay is "sticky clay". Take some moist clay or earth (again, not wet, not dry) and roll it into "snake" then bend the "snake" into an arch. If there are cracks at the top of the arch, it is not sticky clay.

3. Shrinkage Test

3. Shrinkage TestThis is the best test to do to see if your mud mixture will be appropriate for your walls. I suggest making several different mud mixtures altering the quantities of the various components and then do shrinkage tests for all of them to see which one works the best.

To do a shrinkage test, you put your mud into a cylindrical container and ram it. We used large plastic pipes that were cut on the sides and then bound back together with rope. Using two pipes (so the mud did not come out of the seams) worked the best. You add a layer of mud mixture to the depth of your knuckles if you stick your hand into the dirt. Then you ram it until it sounds more like you are ramming stone than mud. You add another layer and continue ramming until the pipe is filled.

When the ramming is finished, remove the pipe. Then on the top of the rammed sample draw a ten centimeter line - clearly marking the ends. (Make sure the measurement is exact.) Then let the sample dry for a couple of days and come back and re-measure the line. The rammed earth should shrink less than 1% if properly mixed.

If your sample shrinks too much, try using less water or adding more sand. It is also better to let the sample (and your walls) dry slowly instead of quickly in the sun.

Shrinkage Test Sample

This mud was rammed in a cylinder and then marked with a 10 cm line.

CREATING THE OPTIMAL MUD MIXTURE

In order to create the optimal mud mixture, it is important to understand the properties of the various materials and how increasing or decreasing their quantities will affect the performance of your mixture.

The most important component of the mixture is the clay. The shape of the clay particles gives it its unique properties. Clay particles are long and round, so they slide over each other easily when they are wet. When the water evaporates, the particles move closer together, making the clay very strong.

Furthermore, the dried clay acts as a water barrier. The molecules pack so tightly that water is not able to enter the wall.

Furthermore, the dried clay acts as a water barrier. The molecules pack so tightly that water is not able to enter the wall. The degree of the stickiness of the clay depends upon its shape. Thinner, oblong shapes are more sticky thank round shapes.

The degree of the stickiness of the clay depends upon its shape. Thinner, oblong shapes are more sticky thank round shapes. While sticky clay is very strong, it also cracks and erodes more easily. It cracks because of the shrinkage. To decrease shrinkage, aggregate is added. The more (and larger) aggregate you have, the less shrinkage occurs.

While sticky clay is very strong, it also cracks and erodes more easily. It cracks because of the shrinkage. To decrease shrinkage, aggregate is added. The more (and larger) aggregate you have, the less shrinkage occurs. While mixtures of 100% clay or clay with only sand would not be good for exterior walls, they would make very strong compressed bricks. (Rammed earth bricks are another great, sustainable building material. You can even make interlocking bricks that eliminate the need for mortar.)

While mixtures of 100% clay or clay with only sand would not be good for exterior walls, they would make very strong compressed bricks. (Rammed earth bricks are another great, sustainable building material. You can even make interlocking bricks that eliminate the need for mortar.)Erosion occurs because of the speed of the water running down a wall. Clay only walls are very smooth, so the water builds up speed and takes particles off of the wall as it runs down. Clay is naturally water resistant, however, so a clay and sand wall would actually have more erosion than a clay only wall even though it would be slightly rougher because the shape of the sand breaks some of the "locks" that the clay particles have with each other. Using a large aggregate, like pebbles or brick chips, however would significantly roughen the wall surface which would decrease erosion. (See Part III - Preventing Erosion for more tips on how to reduce erosion.)

So when creating your mud mixture, you should consider the following factors:

So when creating your mud mixture, you should consider the following factors:1. Will the wall be inside or outside?

Inside walls can have more clay and less aggregate because they will not get wet (and therefore will not be subject to erosion).

2. How many external erosion barriers will you have?

External erosion barriers are architectural elements that break the speed of the water. (See Part III - Preventing Erosion for more details.) The more erosion barriers you have, the less sticky the clay you can use and/or the less aggregate you will have to add. Because we were not able to use the sticky clay on our project, we had to add more external erosion barriers to compensate.

3. What type of mud is available to you?

One of the primary goals of using rammed earth construction techniques is to be sustainable. Consequently you should try to use as many materials from on the site as you can. (This will also help reduce your costs.) Determine what you will need to add to your local mud to make it work for your project.

After you have created your mud mixture, do some shrinkage tests to fine tune your mix.

MIXING THE MUD

Finally, when you actually begin mixing the mud, you want to mix it in smaller batches to make sure that all of the different elements are well blended. (We used small baskets called "tukri" to measure out our parts.) You also need to make sure that you wet the aggregate before you mix it with the mud. Wetting the aggregate makes the mud stick to the sides of it, making it "dirty" for optimal mixing.

The clay should be fairly dry when you first mix it, however. If it is too wet, it will clump together and will not mix in with the other elements. We ran into this problem on our project site and attempted to dry out our sticky clay.

Several of the local children joined us to make mud paddies to dry out the sticky clay. Unfortunately, even with all of the extra help it would have taken us weeks to get enough dried clay to add to the walls. (And our workshop was only 10 days!) Consequently, we decided to just use the clay from the site in our mud mixture and we compensated for the reduced strength by adding additional external erosion barriers.

We also "graded" our earth before mixing it. We put it through a metal screen to separate out the larger particles and then used the fine clay particles in our mixture. Again this helped us achieve an even consistency and a good mix.

We poured the mud through a wire sieve to separate the course particles from the fine.

After you have mixed your mud, you want to make sure that it is damp. Add just enough water so that when you squeeze a handful of your mud mixture together it retains its shape. If the mud is too wet, however, it will be difficult to ram.

You should mix your mud mixture a day before you want to actually ram it. Be sure that you cover your mud mixture so that the water doesn't evaporate. Waiting over night allows the water to more fully penetrate into the clay making it more malleable and ideal for ramming.

We mixed the mud both by hand and using an electric mixing machine.

A NOTE ON ADDING CEMENT

You will notice that cement is not listed above under the possible mud mixture elements. Many people mistakenly believe that adding a little bit of cement to the mud mixture will make it stronger. The opposite is actually true. Because cement particles are small and round, they actually interfere with the natural locking mechanism of the clay particles. As an analogy, picture our two plates of glass with the water between them acting as the clay particles. They move smoothly and when the water evaporates the plates move together and become stronger than just the single glass plate. Now put some sand (our analogy for cement) in between the two glass plates. Not only do they no longer move as smoothly, but when the water evaporates, the two plates of glass no longer sit close together. If we were to apply pressure to them, they would probably crack because of the sand holding them apart in some places.

The moral of the story is: do NOT add cement to your mud mixture!

CLAY PLASTERING

Clay plastering is used to bind elements (foundation, bricks, lintels, etc.) to the rammed earth. Because the clay plastering is wet and is made with sticky clay, it gets into all of the crevices of both the mud and the attaching element, working like a glue.

Here is the recipe that we used for the clay plastering:

- 1 part sticky clay (dried and ground into a powder)

- 1 part red clay from site (sifted through a sieve until fine)

- 2 parts sand

- water

After the dry elements have been mixed, form a pile with a hole in the middle.

Adding Water

Add water into the hole, then bring up the sides to cover the water and let it sit for a few hours. Then come back and mix it with more water until it is the consistency of ceramic slip.

This is Part 2 in a 6 part blog series. For a list of all blog entries on rammed earth construction, please see the index page.

0 Comments:

Post a Comment

<< Home